Material Testing Lab Quality: Revealing the Tricks to Task Resilience

Wiki Article

Developments in Product Screening for Unprecedented Efficiency

In today's rapidly evolving world, where technical improvements are reshaping industries and pressing the boundaries of what was as soon as regarded impossible, the need for products that can hold up against extraordinary problems and deliver remarkable performance has actually become increasingly crucial. As engineers and researchers aim to develop next-generation materials, the capability to accurately evaluate and review their homes has actually never ever been even more vital. This brings us to the intriguing world of improvements in product testing, where sophisticated methods and innovative strategies are transforming the means we optimize and understand product efficiency. From non-destructive screening strategies to the combination of expert system, the opportunities seem countless. So, let us embark on this trip of exploration, as we reveal the impressive developments in material screening and their possible to shape the future of numerous sectors.Non-Destructive Checking Methods

Non-destructive screening techniques are crucial for examining the integrity and integrity of products without creating any damage. These methods play an important role in various industries, consisting of aerospace, auto, building and construction, and production. By using non-destructive testing approaches, designers can assess the properties and attributes of materials, ensuring that they satisfy the called for requirements and requirements.

Another commonly used method is magnetic fragment testing (MT), which is mostly made use of for detecting surface and near-surface defects in ferromagnetic materials. By using an electromagnetic field to the material and after that introducing magnetic fragments, any problems provide can be quickly identified. MT is specifically reliable for identifying splits, lack of combination, and other surface area abnormalities.

Advanced Materials Characterization Approaches

Advanced products characterization approaches are crucial tools for evaluating the residential properties and performance of materials in various sectors. These methods include making use of sophisticated techniques to evaluate and comprehend the microstructure, composition, and actions of materials at the molecular and atomic degrees. By utilizing innovative characterization approaches, researchers and designers can obtain valuable insights right into the structural integrity, mechanical residential properties, thermal stability, and chemical reactivity of materials.One extensively used approach is scanning electron microscopy (SEM), which offers high-resolution photos of a product's surface area. SEM permits the exam of the material's morphology, topography, and essential composition. Another crucial method is X-ray diffraction (XRD), which gives information regarding the crystal framework and stage make-up of materials. XRD is particularly valuable for analyzing the plan of atoms in crystalline materials.

In addition, transmission electron microscopy (TEM) enables researchers to observe the interior structure of materials with atomic resolution. TEM can exposing information such as grain dislocations, flaws, and limits, supplying vital information about a material's mechanical properties - material testing lab. Additionally, spectroscopic techniques like Fourier-transform infrared spectroscopy (FTIR) and Raman spectroscopy can be used to analyze the chemical make-up, molecular structure, and vibrational settings of materials

High-Temperature and Extreme Setting Screening

In order to evaluate the efficiency of products in extreme and high-temperature atmospheres, strenuous screening methods are essential. These screening methods are developed to imitate the problems that materials may come across in real-life applications, such as aerospace, automobile, and energy industries. High-temperature and extreme setting screening intends to examine the habits of materials under extreme warmth, stress, and various other difficult conditions.One frequently used method for high-temperature testing is thermal evaluation. This approach includes subjecting the material to varying temperature levels while measuring its thermal properties, such as thermal growth, warmth capacity, and thermal conductivity. By assessing these homes, scientists can identify exactly how the product will act under various temperature level conditions, enabling them to select one of the most appropriate products for particular applications.

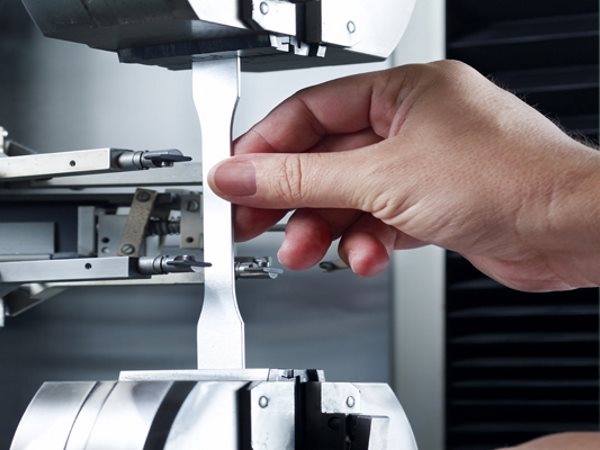

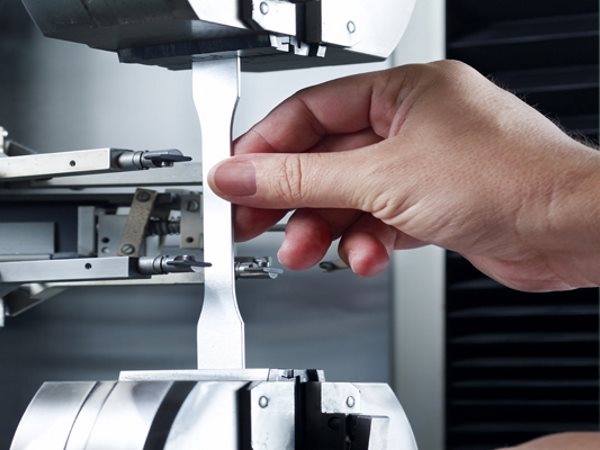

An additional essential facet of severe and high-temperature atmosphere screening is mechanical testing. This entails subjecting the product to mechanical tension at elevated temperature levels, mimicing the problems it might experience in real-world applications. Mechanical screening aids assess the product's strength, ductility, and resistance to deformation and failing under high-temperature and extreme problems.

Additionally, ecological screening is critical to analyze the material's efficiency in extreme problems, such as corrosive settings or exposure to extreme weather. This testing entails subjecting the material to different ecological variables, such as humidity, salt spray, and UV radiation, to assess its resilience and resistance to rust and destruction.

Simulation and Modeling for Product Efficiency

Simulation and modeling play a vital duty in understanding and predicting the efficiency of materials in various applications. With advancements in computational capabilities, researchers and engineers can now model the actions and replicate of materials under various problems, offering beneficial understandings into their performance and assisting in the growth of brand-new products with improved homes.Through simulation and modeling, researchers can research the microscopic and macroscopic actions of products, including their mechanical, thermal, and electric homes. This permits them to predict exactly how materials will behave under various loads, temperature levels, and environmental problems, without the demand for costly and time-consuming experimental testing.

Simulation and modeling techniques additionally allow scientists to optimize product styles and identify potential weak points or failure points. By examining the material's action to various pressures and stimulations, designers can make educated decisions about product choice and style adjustments to boost performance and toughness.

Additionally, simulation and modeling can aid in the growth of materials for particular applications. As an example, in the aerospace industry, scientists can imitate the actions of materials under severe temperature levels and stress to create light-weight yet strong materials for aircraft structures (material testing lab). In the clinical field, simulation techniques can be utilized to study the interactions between materials and biological cells, bring about the advancement of biocompatible materials for implants or drug delivery systems

Combination of Artificial Intelligence in Material Screening

The unification of Expert system (AI) right into material testing has actually reinvented the area, making it possible for scientists to accomplish extraordinary precision and efficiency in examining material performance. AI algorithms can refine and assess huge amounts of information, recognizing patterns and relationships that may not be instantly apparent to human researchers. Our site This allows for more specific and extensive More Bonuses testing, resulting in a much deeper understanding of product behavior.One application of AI in product testing remains in the growth of predictive designs. By educating AI algorithms on huge datasets of material residential properties and performance, researchers can produce models that can precisely anticipate the habits of new materials under various conditions. This can greatly quicken the product advancement procedure, as it allows researchers to display and prioritize products with wanted buildings.

Along with predictive modeling, AI can additionally be made use of to enhance testing treatments. By examining historic testing data, AI formulas can recognize the most effective and insightful tests to execute, lowering the time and resources required for product analysis.

In addition, AI can assist in the identification of anomalies or defects in materials. By contrasting examination results versus expected results, AI formulas can identify discrepancies and alert scientists to potential problems. This can help improve quality assurance procedures and make sure the usage of products that fulfill the called for specifications.

Conclusion

By assessing these properties, scientists can determine exactly how the product will certainly behave under different temperature conditions, enabling them to pick the most appropriate products for specific applications.

The incorporation of Artificial Intelligence (AI) into product testing has transformed the area, allowing researchers to attain unprecedented precision and efficiency in examining material efficiency.In conclusion, developments in material testing techniques, characterization approaches, high-temperature and severe environment screening, and the integration of synthetic knowledge have substantially added to the advancement of unmatched efficiency in materials. These innovations have permitted for the identification of product homes and behaviors, allowing the layout and optimization of materials for numerous applications. material testing lab. With more study and technical advancements, material testing will certainly continue to Read Full Article play a critical role in pushing the borders of product efficiency

Report this wiki page